Often our Freight Car Friday features focus on broader topics. This week we devote our blog to one specific class of car – the prototype for our Lionel and American Flyer reefers.

Pacific Fruit Express

Lionel’s upcoming American Flyer PFE reefer represents a car following the split of the company with SPFE markings and a Perishable Fruit Express logo over the UP shield.

Created in 1906, Pacific Fruit Express grew to operate the largest fleet of refrigerated rail cars in the world. By the 1970s, their fleet was more than double the size of their nearest American competitor. Consequently it should come as no surprise that the company was a leader in the field of refrigerator car design and utilization.

PFE was owned jointly by Southern Pacific and Union Pacific. Depending on the financing behind a particular order for cars, the reefers could be seen with PFE, SPFE or UPFE reporting marks. The emblems of both companies were displayed on the sides of the cars until 1978. In that year, the company was split with cars going into each railroad’s respective operating fleet.

In addition to the cars, PFE maintained its own ice making and loading facilities and car shops and, until 1961, built most of the company’s equipment in-house.

Evolution of the Mechanical Reefer

PFE was not the first to develop the mechanical reefer. That credit belongs to Fruit Growers Express. The lag in development however has little to do with the management at PFE and much to do with the differences between Florida and California oranges. Florida oranges are more favorable for juicing and this juice concentrate needs to be shipped at a freezing temperature which requires mechanical refrigeration. California’s produce on the other hand was still overwhelmingly being shipped fresh, for which icing did just fine.

PFE’s first mechanical reefers came in 1952. The switch to mechanical reefers didn’t happen overnight however. The last ice reefers were delivered five years later in 1957. Nearly 1500 ice cars were still on the roster in 1975 and some lasted as long as 1980 in ventilator service for loads requiring ventilation in cool weather without refrigeration. The switch to mechanical refrigeration was partly a matter of cost efficiency and also in part due to a shifting in the types of produce being transported by rail to increased numbers of bulk, frozen foods over fresh produce. The latter was increasingly moving by truck but also generally decreasing as a part of the American diet overall. (Interesting how a study of freight cars can provide a look into so many things!)

As is nearly always the case, when the needs of the customers changed so too did the PFE car fleet. Mechanical reefers grew larger to handle greater capacities and maximize the efficiencies of rail transport. Whereas the overwhelming majority of iced reefers were 40′ long, 50′ mechanical reefers were more common beginning in the 1950s and grew to nearly 57′ in 1963. Capacity of the 57′ reefers was nearly double that of the older 40′ cars.

R-70-20

Jumping ahead to 1969, we arrive at the prototype for our O and S scale models. The R-70-20 represented the last major design change for PFE reefers. The class designation stands for Refrigerator – 70 tons nominal capacity – 20th chronological design. These cars were built at Pacific Car and Foundry’s Benton, WA facility. PC&F supplied 1200 cars in 1969 and an additional 1200 in 1970. That second order was evenly split between SP and UP with the UP cars being given the class R-70-21.

The R-70-20 offered several design changes from the previous models. One was an increase in the width of the doors from 9′ to 10′ 6″. This was done to make it easier for fork lifts to load / unload the car without damaging the car sides. The door tracks required special attention to ensure that a single worker could still open the heavy doors by hand. (Failing this, workers were commonly known to use their forklifts to open the car doors causing frequent damage.)

Another change in this design was the roof. Previous cars all had a lightly peaked roof. The R-70-20 is rounded, but tapers to a flatter profile with rounded corners near the car ends. Changes to the number and patterns of stiffening ribs on the roof is one of the small detail changes found in subsequent designs.

After being rebuilt with new refrigeration units, UP’s fleet took a coat of white and wore ARMN reporting marks.

The initial order of cars used either Keystone or Hydra-Cushion underframes. Both types would be used in subsequent classes as well. Visually the only spotting feature is a conical vent in the center of the underframe on the bottom of the Hydra-Cushion cars.

The R-70-20 was also the first class of PFE reefers to be delivered new with the new ACI car reader tags installed.

The only other significant change to subsequent classes (R-70-22 through 25) was substation of Type F couplers on UPFE cars. More obvious than structural or mechanical changes were alterations to the markings on the cars reflecting the corporate evolutions of the period.

The initial order of R-70-20 cars came with PFE reporting marks with white letters on a small black square. This was done to improve their visibility on the orange car. Both the UP and SP heralds were used. It is interesting to note that the UP shield was always closest to the mechanical, or “A” end of the car, so they swapped places on the left / right sides. Both the heralds were in the new “silhouette” version with the UP having full “UNION PACIFIC RAILROAD” lettering. On the other side of the car, “PACIFIC FRUIT EXPRESS” was spelled out in large black letters with the first letter of each word in white with black outline.

All total, the R-70-20 through 25 classes would include 3800 cars on PFE. Subsequent orders would see small changes to all of these graphics and the reporting marks. After the split, reporting marks on the first cars were also changed by adding an S or U as appropriate. Stickers were also applied over the other road’s herald, again with much variation to make car spotting and modeling more interesting!

BNSF cars can also be found in brown. Note that whatever color the railroads painted the sides, roofs were traditionally kept white.

Complete repaints started coming in the 1980s with UPFE cars getting repainted yellow with full UP markings. Southern Pacific retained Pacific Fruit Express as the name of the division operating independently within the company. SPFE cars were typically repainted white with a great variety in lettering styles and colors.

Many cars were sold or scrapped as the need for mechanical reefers was further replaced by trucks during the coming decades. What was left of the two fleets was reunited in 1996 through the UP-SP merger.

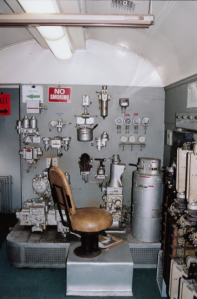

Starting in the early 2000s, with the cars now having more than 30 years of service behind them, the remaining reefers were given significant overhaul. The most obvious change to the cars came with the replacement of the diesel refrigeration units with more modern and efficient versions. These mount vertically on the inside bulkhead and look like the units applied to refrigerated trailers. The installation also requires the removal of the last roof “panel” over the unit.

While PFE helped drive the design and purchased the majority of these cars, similar reefers were also sold to other companies. The second-largest fleet of these cars would come to be owned by BNSF, tracing its roots to the Northern Pacific and Great Northern. BNSF’s cars too have undergone a similar rebuilding in the past decade.

The basic body style – with the large plug door, tapered side posts terminating short of the lower sill and roof line and rounded roof with tapered ends – became a common trademark for PC&F insulated boxcars as well. In spite of their age, rebuilding and retirement to the large-scale shift of perishable loads to refrigerated trucks, the familiar face of the R-70-20 continues to have a presence on railroads to this day.